|

|

More

|

|

|

||||||||||||

|

|||||||||||||||

|

|

|

|||||||||||||||

|

|||||||||||||||||

PROFIBus PROTOCOL

Technology Overview

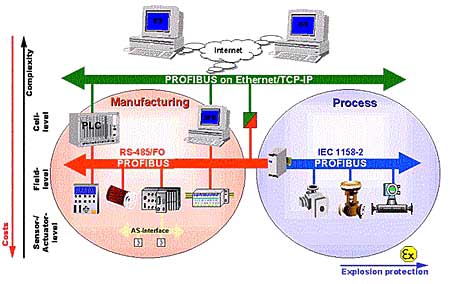

Communication in automation is becoming increasingly direct, horizontally at field level as well as vertically through all hierarchy levels. Depending on the application and price, graduated and matched industrial communication systems offer the ideal preconditions for transparent networking in all areas and levels of the automation process. Profibus offers such a graduated system with the Ethernet-based PROFInet, the fieldbus PROFIBUS and other systems like the sensor/actuator bus AS-Interface

At sensor/actuator level signals of binary sensors and actuators are transmitted via a sensor/actuator bus. At this level a particularly simple, low-cost installation, through which data and 24-volt power supply can be transmitted using a common medium, is an important requirement. AS-Interface is a suitable bus system for this type of application.

At field level the distributed peripherals, such as I/O modules, measurement transducers, drive units, valves and operator terminals communicate with the automation systems via an efficient, real-time communication system. The transmission of process data is implemented cyclically, while alarms, parameters and diagnostic data also have to be transmitted acyclically if necessary. PROFIBUS meets these requirements and offers a transparent solution for manufacturing as well as for process automation.

At cell level the programmable controllers such as PLC and IPC communicate with each other. The information flow requires large data packets and a large number of powerful communication functions. Smooth integration into company-wide communication systems, such as Intranet and Internet via TCP/IP and Ethernet are important requirements.

The IT revolution in automation technology is opening up new savings potentials in the optimisation of systems processes and makes an important contribution towards improved use of resources. Industrial communication systems have assumed a key function in this respect.

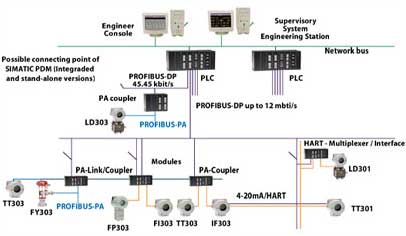

A Detailed Typical Profibus System

PROFIBUS is a vendor-independent, open field bus standard for a wide range of applications in manufacturing and process automation. Vendor-independence and openness are ensured by the international standards EN 50170, EN 50254 and IEC 61158.

PROFIBUS allows communication between devices of different manufacturers without any special interface adjustment. PROFIBUS can be used for both high-speed time critical applications and complex communication tasks. Through its continuing further technical developments, PROFIBUS is still the industrial communication system prepared for the future.

PROFIBUS offers functionally graduated communication protocols (Communication Profiles): DP and FMS. Depending on the application, the transmission technologies (Physical Profiles) RS-485, IEC 1158-2 or fiber optics are available. In the course of further technical development, the PROFIBUS User Organisation is currently working on the implementation of universal concepts for vertical integration on the basis of Ethernet TCP/IP. Application Profiles define the options of protocol and transmission technology required in the respective application area for the individual device types. These profiles also define vendor-independent device behavior.

PROFIBUS defines the technical characteristics of a serial field bus system with which distributed digital programmable controllers can be networked, from field level to cell level. PROFIBUS is a multi-master system and thus allows the joint operation of several automation, engineering or visualisation systems with their distributed peripherals on one bus.

See some Smar installations and applications:

Title: Paint/Brazil

http://www.profibus.com/imperia/md/content/pisc/

profinews/PROFINews20.pdfTitle: Paraguay Brewing

http://www.profibus.com/imperia/md/content/pisc/

profinews/PROFINews22.pdfTitle: Brazil/Iron Ore

http://www.profibus.com/imperia/md/content/pisc/

profinews/PROFINews23.pdfTitle: Brazil/Lime

http://www.profibus.com/imperia/md/content/pisc/

profinews/PROFINews24.pdfTitle: Brazil/Oil Refinery - "Greatly improves maintenance"

http://www.profibus.com/imperia/md/content/pisc/

profinews/PROFINews25.pdfTitle: RPA AIMS to be Best Known Association in Brazil

http://www.profibus.com/imperia/md/content/pisc/

profinews/PROFINews26.pdfTitle: "Brazil: Comestible Oil Refinery"

http://www.profibus.com/imperia/md/content/pisc/profinews/PROFINews25.pdf#page=6Title: "Brazil: Water Treatment"

http://www.profibus.com/imperia/md/content/pisc/

profinews/PROFINews29.pdfOur Profibus products:

http://www.smar.com/products/technology.asp#profibusFor more information, visit the PROFIBus site at:

http://www.profibus.org